Superior Column Protection

RAMGuard™ provides superior rack column protection with its patented Rubber Armored Metal design. Molded of energy absorbing rubber with a "U-shaped" steel insert and force distributing rubber voids, RAMGuard absorbs significantly more energy during impact than most column protection devices offered today.

RAMGuard™ Advantages

- Protects rack structures from frontal, angled and side impacts

- Significantly lowers impact damage to pallet rack columns

- Requires no hardware or straps to retain the guard on column

- Endures many impacts with no loss of performance

- Significantly outperforms most plastic guards commonly used today

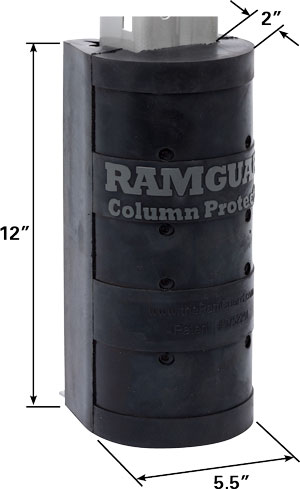

Available in 12-inch heights, RAMGuard snaps onto rolled or structural steel columns 3-inches wide and

up to 3-inches deep.

Steel Reinforced

Why Invest in RAMGUARDS?

There is a wide range of products designed to help protect pallet rack columns from the everyday abuses that commonly occur in busy warehouse environments. These products include steel reinforced columns, slat-back or offset frames, floor-mounted steel guards, bumpers, barriers and after market attachable guards. Each of these serves a purpose and makes sense in different applications.

However, there has never been anything like RAMGuard!

First, it provides maximum impact protection against costly column and frame damage. It's solid rubber construction with a steel plate insert is tougher than any plastic guard and most other products on the market.

Second is its durability. Because of its robust construction properties, The RAMGuard can withstand repeated impacts with no loss in protective qualities. During testing, The RAMGuard sustained 25 impacts with no loss in effectiveness.

Third, toolless installation with no anchors or bolts like steel aftermarket guards.

Finally, new High Visibility Velcro straps help fork lift operators see the guards to safely guide their loads into position. They also provide additional retention strength in high traffic/contact areas.

RAMGuard's Construction

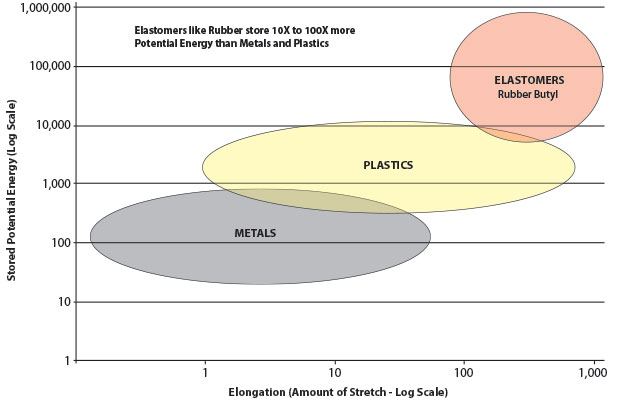

After nearly two years of development, testing and proto-type designs, the new patented RAMGuard delivers the greatest impact resistance available in aftermarket column guards. Through extensive testing and evaluation, a specific rubber compound was formulated to provide a balance between durability, density and impact absorption qualities. The chart below shows the energy absorbing capacity of various materials that are commonly used in column guards. Clearly, this shows elastomers offer some far greater absorbing properties than other materials. The results speak for themselves!

Contact RamGuard™ at 814.347.1174 or your local supplier for more information or a quotation.

Watch Impact Testing

Impact testing to FEM 10.2.02 standards has shown the RAMGuard dissipates more impact energy and better distributes impact forces than competitive guards resulting in no damage to the column or the guard. During extensive frontal and 45° angle testing, the same RAMGuard protector easily withstood more than 20 identical hits without allowing any damage to the column.

- Energy absorbing elastomer guards outperform plastic guards

- Elastomer guards lower the peak acceleration levels at the column

- Elastomer guard with steel reinforcement will endure multiple impacts with no loss of performance*

Superior Rack Protection

RAMGuard™ provides superior rack column protection with its patented Rubber Armored Metal design. Molded of energy absorbing rubber with a "U-shaped" steel insert and force distributing rubber voids, RAMGuard absorbs significantly more energy during impact than most column protection devices offered today.

Fit, Sizes and Dimensions

| Size | 12" high 5.5" wide |

| Weight | 9 lbs |

| Fits Columns | 3" wide and up to 3" deep |

| Testing | Test Setup to meet European FEM 10.2.02 Standard |

| Fits all 3" wide face columns | |

Know Your Column Size

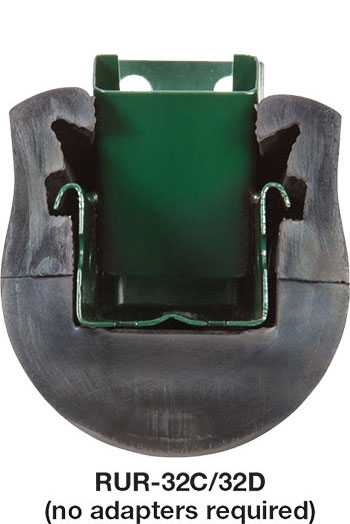

Rubber adapters for the smaller 3 x 1-5/8, 3 x 2-1/4 and 3” Structural columns. Each guard requires two adapters per guard. Adapters are sold in kits containing two adapters.

What you need to know about Pallet Rack Protectors

Browse the following considerations to help make informed decisions when investing to protect your Pallet Rack Storage System.

Storage rack systems are typically a bee hive of activity. Whether the rack structure is in an industrial manufacturing plant or a high volume distribution center, these storage systems need care and protection. Certain areas of all warehousing operations have high traffic zones. It is usually, here you find the greatest need to provide extra protection from fork lift frontal and side impacts. Even the most experienced drivers will admit that under pressure a significant impact on an upright frame can occur and eventually probably will. So what are your options to plan for the inevitable rack damaging impact?

There are a three ways to reduce rack damage.

First, improve fork lift driver training and accountability for rack impacts.

Second, for new installations, order pallet rack with column reinforcement on the lower portion, or order rack uprights with a set back or slant back on the lower portion of the column.

Third, is to add an aftermarket rack column guard. There is a wide range of options from plastic to steel or a rubber/steel mounted protector with high impact resistance.

Fork lift impact testing and simulations have shown the ideal guard should offer impact resistance and/or high energy absorption characteristics. Steel and steel/rubber guards offer different types of protection. All steel protectors offer impact resistance, but no impact energy absorption. If the steel guard is damaged, it is likely the frame and concrete floor will be as well. Rubber/steel guards offer high impact absorption while retaining the benefit even after an impact.

New pallet rack can be ordered with reinforcements or set backs in the lower portion of the column or upright to minimize rack damage. Aftermarket rack column guards fall into three categories… steel, rubber/steel or plastic. Steel guards are common and either bolt on or are mounted in the concrete floor with anchors. Both styles require installation. Rubber/steel guards offer tooless snap-on convenience with high impact energy absorption qualities. Plastic rack guards come in a wide range of sizes and shapes and snap-on to columns some require straps.

Rack guards can be attached to the upright column by bolting on to the frame, anchoring into the concrete in front of the upright, anchoring and bolting to the upright, snapping on around the frame, or can be strapped to the rack's upright frame. Regardless of the style protector you choose, consider the cost of installation and the likelihood of eventual replacement.

Not all guards need to be anchored using professional installation. Some steel column protectors anchor to the concrete floor in front of or around the upright frame. Rubber/steel guards snap on around the frame and can be secured with heavy-duty straps. Plastic guards attach the same way. Other steel guards can bolt onto the face of the frame minimizing costly anchor installation.

There are fewer options for protecting the upright frames once pallet rack is in position and loaded with product. In this case, bolt-on or snap-on/strap-on column guards are the best choice. Impact testing indicates either steel bolt-on or the rubber/steel snap-on protectors offer maximum impact resistance.

Aftermarket guards can be purchased direct, through material handling distributors, dealers, catalog houses, and industrial supply houses. Most offer online shopping for fast service or calling a material handling professional to review your needs and provide installation services as well. If you opt for a snap-on guard or a guard that does not require installation, buying online and having them shipped direct to your facility is probably most efficient.

They are all quite different in what they do and how they protect the rack's frame.

Steel guarding products are the most common type of protector and are usually installed while the pallet rack storage system is being installed. Steel guards bolt on to the frame or they are anchored in front of the upright. They require installation by a professional and are designed to "reinforce" the existing steel column. See the diagram at the right.

Attached steel guards are strong and protect the roll formed or structural steel frame from buckling. However, they do not absorb energy from the impact. Those impact forces transfer to the upright and its anchor points. Depended on those forces, the anchors and base plate will hold or they will weaken the anchor or the concrete floor. Damage may not be noticeable. If the damage is visible, the upright rack frame may need to be replaced, or the floor may need to be repaired.

Rubber/Steel column protectors are quite heavy, nearly 10 pounds, and are made from dense rubber with a quarter-inch steel plate molded into the guard. The "U" shaped plate is effective on angled impacts. The space between the plate and the upright is filled with small voids in the rubber to allow greater impact energy dissipation.

The most significant difference between a steel guard and the rubber/steel snap-on type is impact energy dissipation. The three elements in the rubber/steel guards are designed to dissipate or absorb the impact energy, not just blunt it. These protectors have proven in fork lift impact testing to be able to withstand dozens of impacts while showing no signs of deformation or degradation in effectiveness.

Plastic guards can be the lowest cost type of guard. They offer some impact resistance, but typically deform during impact and will need to be replaced.

Pallet rack column protectors range from $10 to well over a $100 including shipping and installation. In some cases a rack protection system, might actually cost more than the frame it is protecting. That investment can easily be justified when considering the true replacement cost of an upright. That cost includes ordering a replacement frame, unloading the rack, disassembling multiple tears of beams, frame and beam replacement, and reloading the storage rack.

A quality guard should cost between $20 and $45 in quantity.

Like any protective or safety product, the value of a rack guard is calculated by totaling the upfront cost, installation and maintenance of the guard(s) versus the repair or replacement cost of an upright.

A typical 40-foot 36-inch deep upright might cost between $155 and $250 per frame. Then, add the cost to unload the rack, order a new upright, shipping, installing, anchoring and reloading the rack and this process turns into an expensive venture.

If an inexpensive guard may or may not protect the rack structure, then it has little value. Whereas, spending more on the initial purchase of a protector knowing that it will protect the rack upright is worth the investment.

As you evaluate the price/performance of rack protectors, consider the ability of that rack protector to withstand multiple impacts without needing to be replaced. A $40 to $50 rack guard that saves a company the replacement cost of an upright two, three or four times… becomes a very good investment. $40 upfront to save a couple of thousand dollars.

Yes, there are a few innovative rubber and rubber/steel column guards, although not many. The snap-on RAMGuard is solid rubber with a 1/4-inch U shaped steel plate molded inside. There is a tall steel guard with a rubber backer that needs to be anchored to the floor. These are the current models we are aware of at this writing.

With the strong advantages of the rubber/steel combination of impact resistance and energy absorbing features, we are sure there will be more competitors in the group.